Test & Measurement

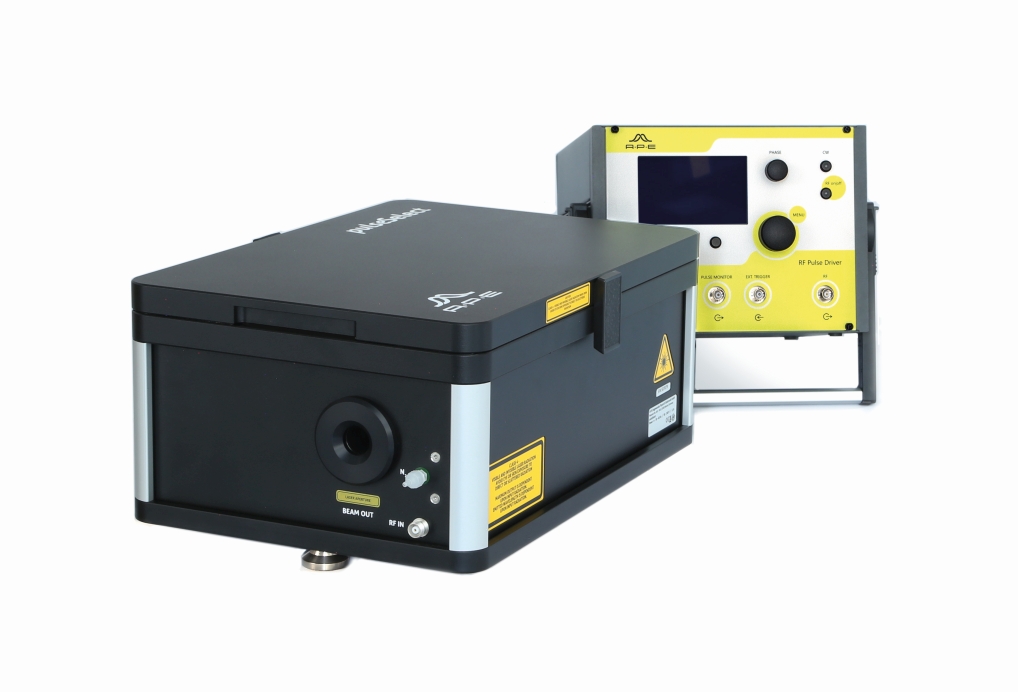

APE GmbH is a market leading developer and manufacturer of components and systems for the ultrafast laser industry: precision, quality and service from autocorrelator to wavelength measurement, from acoustooptics to synchronously pumped optical parametric oscillators.

APE autocorrelators are used to measure the pulse duration of femtosecond and picosecond laser systems. The technology is based on either Second Harmonic Generation (SHG) detection or Two Photon Absorption (TPA) detection principle.

Learn More

The World leader in material testing Instruments.

Part of Instron's protfolio is

- Instron® Equipment - Tensile and Compression

- Dynamic Testing - Both Servohydraulic and Electric solutions

- Torsion Machines

- Bi-Axial Testing - Linear and Torsion testing at the same time (Specially designed for Bio-Medical applications) SATEC™ Equipment)

- Polymet testing - HDT, Vicat and MFI

- Impact Testers for both polymers and metals

We also offer accessories such as: Extensometers, Grips, Load Cells, and More.

The 6800 Series Universal Testing Instruments offer exceptional performance and are designed with enhancements that deliver unparalleled accuracy and reliability, improved ergonomics, and an enhanced overall experience for the operator.

Learn More

ElectroPuls systems are the established materials testing instruments using patented linear motor technology. Offering slow-speed static and high-frequency fatigue testing, this versatile testing capability means ElectroPuls systems are ideal for any lab or office space.

Choose from axial only or combined axial-torsion systems that can deliver up to 10kN and 100Nm.

Learn More

Servohydraulic systems are the workhorse of any laboratory. They can perform a wide variety of low and high cycle fatigue, crack propagation, fracture toughness and other dynamic tests.

Learn More

Instron pendulums are designed to meet the growing demand for accurate and repeatable impact testing on a wide range of materials.

Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement.

Learn More

The Instron® MFi Series of melt flow index testers are specifically designed for easy and accurate measuring of melt flow rate (MFR) and melt volume rate (MVR) according to Melt Flow Rate testing procedures determined by ASTM D1238 and ISO 1133 standards.

Learn More

The design of the HV Systems and BLUEHILL® HV Software is based on the full understanding of customers needs for both an enhanced user-experience and outstanding productivity, making materials testing SIMPLER, SMARTER, SAFER.

Learn More

Keopsys manufactures a large range of standard and custom-designed optical fiber amplifiers and lasers for fiber and free space optical communication systems, CATV, component testing, remote sensing, spectroscopy, material processing, military and research applications. High output powers are achieved through the use of double cladding fibers pumped by broad stripe diodes. A variety of pumping techniques are utilized, each optimised for a specific application

• Laboratory Fiber Amplifiers and Lasers

• Data Transmission EDFA’s

• Industrial Fiber Light Sources Scientific, Military & Industrial

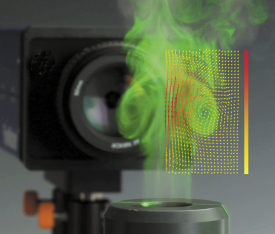

LaVision‘s imaging and sensor systems provide market-driven measurement solutions for flow field imaging, combustion, spray and particle analysis and materials testing.

Our diagnostic instruments are based on optical techniques such as:

- Particle Image Velocimetry (PIV)

- Laser Induced Fluorescence (LIF)

- Light Scattering

- Digital Image Correlation (DIC).

The LaVision FlowMaster system family evaluates three-dimensional velocity vector fields from scattered light patterns of particles or droplets seeded into the flow (liquid or gas).

Learn More

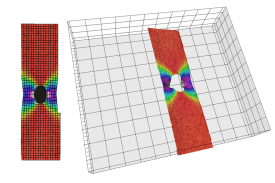

StrainMaster from LaVision is a state-of-the-art, non-intrusive optical tool for shape, strain and deformation analysis of solid, granular and liquid subjects.

Learn More

Luna Inc is a leader in Optical Technology

They accelerate the process of bringing unique capabilities and revolutionary products to market that solve today’s business challenges and address the needs of tomorrow.

Luna offers a range of fiber optic sensing products designed for use across multiple markets and applications including strain and temperature. Whatever your application, Luna offers a product ideally suited for your needs.

Luna has several customers in Israel

The ODiSI 6000 Series is a novel measurement system specifically designed for advanced materials and systems.

The ODiSI provides thousands of strain or temperature measurements per meter of a single high-definition fiber sensor.

The high-definition data can fully map the contour of strain for a structure under test or the continuous thermal profile of a process in real-time.

Learn More

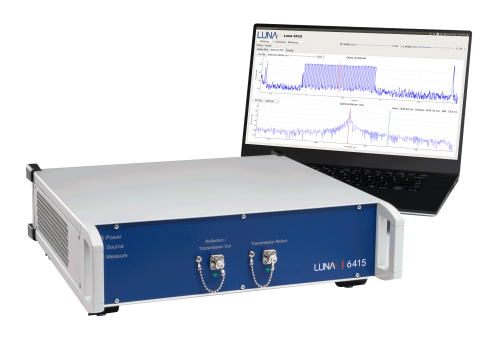

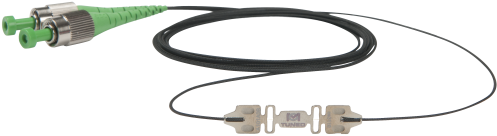

The Luna 6415 is a fast and simple-to-use analyzer for passive optical components and modules. The Luna 6415 extends the industry-leading optical frequency domain reflectometry (OFDR) platform from Luna Innovations to manufacturing test and quality control applications.

Unlike traditional passive component testers, the Luna 6415 measures and analyzes the Insertion Loss (IL) and Return Loss (RL) distribution, as well as length, working in either reflection or transmission. The Luna 6415 features extremely high sensitivity, 20 μm spatial sampling resolution, and very fast scanning for high test throughput.

Learn More

The Luna OBR 4600 is part of Luna’s award winning Optical Backscatter ReflectometerTM product line. For strain and temperature sensing applications the OBR 4600 offers the user the highest degree of flexibility in customizing measurements to the application as well as the longest available sensing range.

The distributed sensing option can provide sub cm spatial resolution with sensors up to 2 kilometers.

Learn More

Optical Vector AnalyzerTM The Luna OVA 5000 is the fastest, most accurate and economical tool for loss, dispersion and polarization measurements of modern optical networking equipment.

It is the ideal device for single-connection, all parameter characterization of fiber components from couplers to specialty fiber and everything in between (Fiber Bragg Gratings, arrayed waveguide gratings, free-space filters, tunable devices, amplifiers, etc.), all with a single sweep of a tunable laser.

Learn More

The si155 is an industrial grade fan-less optical sensing interrogator. Featuring both static and dynamic full spectrum analysis, the si155 provides long-term, reliable and accurate measurements of hundreds of sensors on 4 parallel, 160 nm wide channels.

Learn More

The si255 is an industrial grade fan-less optical sensing interrogator. Featuring both static and dynamic full spectrum analysis, the si255 provides long-term, reliable and accurate measurements of nearly 1000 sensors on 16 parallel, 160 nm wide channels.

Learn More

Optical sensors provide an alternative to traditional electrical sensors for many applications, with high accuracy, long term stability, streamlined installation, and premium performance under harsh environmental conditions. These optical sensors offer immunity to EMI and extraordinary resistance to mechanical fatigue.

- Strain

- Temperature

- Displacement

- Accelerometers

Learn More

Laser beams in industrial applications, whether they be CO2, Nd:YAG- diode or fibre lasers, work with invisible beams in the infra-red or near infra-red spectral range (NIR). Hence changes in beam quality or power cannot be detected visually, and only become evident from the outcome of their application. Under some circumstances, this results in very expensive rejects being produced. If the deterioration in quality is not recognised in the manufacturing process, this usually results in the subsequent failure of the product in use, with consequences for the manufacturer of rectification, replacement and loss of image.

This is where PRIMES beam diagnostics devices for measuring beam quality, focusability and laser power come in. Process monitoring in production with laser beam diagnostics devices by PRIMES enables consistent quality assurance and allows the timely detection and elimination of malfunctions of laser beams.

Psylotech endeavors to build a world-wide community around multi-scale mechanical testing.

Including testing with:

- xTS – X-ray Tomography

- µTS – Optical/Confocal Microscopy

- X-ray Diffraction

- SEM